Importance of P&ID Symbols in Streamlining System Integration

Piping and Instrumentation Diagrams P&IDs are essential tools in the design, installation, and operation of complex systems across various industries such as chemical, petrochemical, and process engineering. These diagrams visually represent the equipment, piping, instruments, and control devices within a system, ensuring that all components are accurately connected and functioning cohesively. The importance of P&ID symbols in streamlining system integration cannot be overstated, as they offer a standardized approach to representing system components, reducing errors, and enhancing communication between engineers, operators, and technicians. One of the most significant advantages of using P&ID symbols in system integration is their role in standardizing designs. In complex engineering projects, system integration involves connecting various subsystems each with its own specifications, requirements, and operational characteristics. P&ID symbols provide a universal language that ensures all stakeholders, including design engineers, construction teams, and maintenance personnel, can understand the system’s layout and function. This standardization eliminates confusion that might arise due to varying interpretations of system components, leading to a smoother and more efficient integration process.

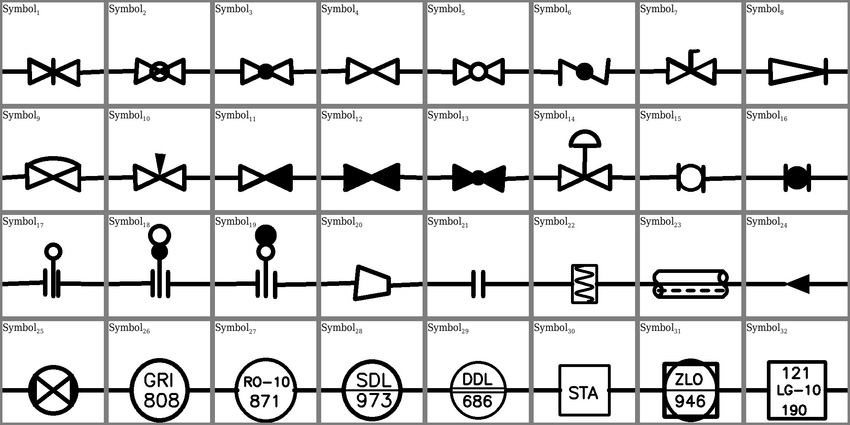

Moreover, the use of standardized p&id symbols helps in preventing potential errors during the installation and commissioning phases. Each symbol is carefully designed to represent specific components such as pumps, valves, pressure transmitters, and heat exchangers. This clarity helps to avoid mistakes when installing or connecting these components, as engineers can easily verify their placement and function based on the diagram. Additionally, the symbols provide detailed information on how the equipment should be wired or piped, which is essential for ensuring the proper flow of materials, energy, or fluids through the system. By following the diagram closely, system integrators can minimize the risk of installation faults or mismatches, which can lead to costly delays or operational inefficiencies. P&ID symbols also play a critical role in optimizing system maintenance and troubleshooting. Once a system is up and running, any malfunctions or failures can disrupt operations, leading to downtime and increased maintenance costs. However, when the system is clearly documented with P&ID diagrams, identifying the root cause of an issue becomes easier.

The symbols on the P&ID represent the exact locations of instruments, valves, and other critical equipment, allowing maintenance personnel to quickly pinpoint potential problems and take corrective action. This streamlines the troubleshooting process, minimizes downtime, and ensures that repairs are carried out efficiently. Another key benefit of P&ID symbols is their contribution to safety and compliance. In highly regulated industries, safety is paramount, and every aspect of system integration must adhere to strict guidelines and regulations. P&ID diagrams can be used to illustrate safety features such as emergency shutdown systems, safety relief valves, and hazard detection equipment. By using the correct symbols to represent these safety components, engineers and operators can ensure that the system complies with industry standards and regulations. This not only helps in preventing accidents and hazardous situations but also ensures that the system remains functional and compliant over time. Engineering projects often involve cross-disciplinary teams, including mechanical, electrical, and control engineers, who need to work together to integrate their respective subsystems into a cohesive system.